Food preservation has been a critical aspect of human society for centuries. The need to preserve food has led to the development of various preservation methods such as canning, smoking, and dehydration. However, these traditional methods have some limitations, such as the loss of nutrients and flavor. The vacuum freeze dryer has revolutionized food preservation by overcoming these limitations. This article explores the science behind vacuum freeze drying and how it is changing the food preservation industry.

Introduction to the Vacuum Freeze Dryer

Vacuum freeze drying is a relatively new food preservation method that has gained popularity in recent years. It is a process that involves removing moisture from food products while preserving their nutritional content and flavor. Vacuum freeze dryers work by freezing the food product and then subjecting it to a vacuum that removes the ice crystals through sublimation. The result is a product with a longer shelf life while maintaining its original appearance and texture, retaining all its flavor, protein and vitamins and easy to transport without refrigeration.

How The Vacuum Freeze Dryer Work

The vacuum freeze drying process involves three stages: freezing, primary drying, and secondary drying. Freezing is the first stage where the food product is frozen at a low temperature. The low temperature causes the water in the food to freeze, forming ice crystals. The next stage is primary drying, where the pressure in the chamber is reduced, and heat is applied. The low pressure causes the ice crystals to sublimate, turning them directly into water vapor. In the final stage, secondary drying, heat is applied to remove the remaining water molecules from the food product.

Benefits of Vacuum Freeze Drying

One of the primary benefits of vacuum freeze drying is that it preserves the nutritional content and flavor of the food product. Unlike traditional preservation methods such as canning and dehydration, vacuum freeze drying does not involve high temperatures that can destroy the nutritional content and flavor of the food product. Vacuum freeze-dried food products retain their original taste, texture, and nutritional value for an extended period.

Another benefit of vacuum freeze drying is that it extends the shelf life of food products. The removal of moisture from the food product inhibits the growth of microorganisms that cause spoilage. Vacuum freeze-dried food products make them ideal for long-term storage.

Applications of Vacuum Freeze Drying in Food Preservation

Vacuum freeze drying has numerous applications in the food preservation industry. It is commonly used to preserve fruits, vegetables, meats, and seafood. In the fruit and vegetable industry, vacuum freeze-dried products are used to make snacks, instant soups, and beverages. In the meat and seafood industry, vacuum freeze drying is used to preserve meat, poultry, and fish products. Vacuum freeze-dried meat products are popular among backpackers and hikers as they are lightweight, easy to transport, and have a long shelf life. And because freeze-drying not only preserves the rich nutritional content of meat, but also retains the original flavor of the ingredients, more and more pet foods are starting to use freeze-drying technology.

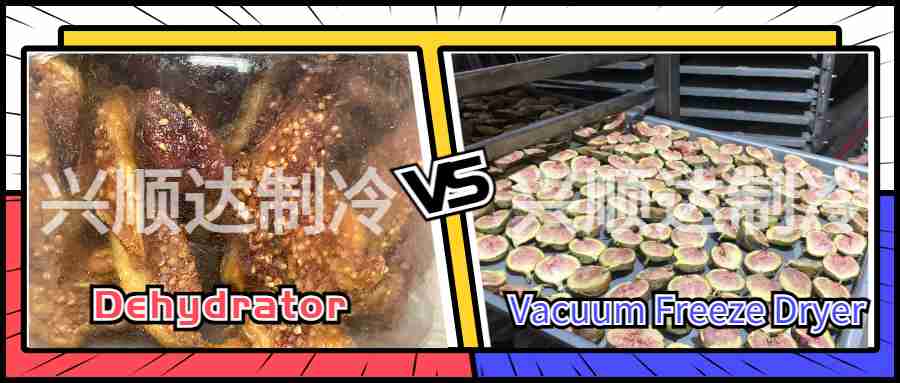

Comparison with Other Food Preservation Methods

Vacuum freeze drying has several advantages over other food preservation methods such as canning and dehydration. Canning involves high temperatures that can destroy the nutritional content and flavor of the food product. Dehydration also involves high temperatures that can cause the food product to lose its nutritional value and flavor. Vacuum freeze drying, on the other hand, does not involve high temperatures, making it a better option for preserving the nutritional content and flavor of the food product. Juan Wang and his colleagues tested how vacuum belt drying, freeze-drying, and air-drying (Dehydrators) affected the quality of banana powder. They discovered that freeze-drying was the optimal way to make banana powder with the most pleasant smell.

In this research report, Juan Wang and his colleagues tested how vacuum belt drying, freeze-drying, and air-drying (Dehydrators) affected the quality of banana powder. They discovered that freeze-drying was the optimal way to make banana powder with the most pleasant smell.

Vacuum Freeze Drying Equipment and Cost

Vacuum freeze drying equipment varies in size and complexity, depending on the application. The small-scale vacuum freeze dryer can cost a few thousand dollars, while large-scale units can cost anywhere from $35,000 to $1,200,000 or more (commercial vacuum freeze dryer), depending on the size and features.

The cost of vacuum freeze drying depends on the type of food product and the volume of production. Taking our company’s medium-sized freeze dryer as an example, freeze-drying one kilogram of raw material only requires 1.8 kWh of electricity.

Future of Vacuum Freeze Drying in Food Preservation

The demand for vacuum freeze-dried food products is expected to increase in the future due to their nutritional value, flavor, and extended shelf life. The technology is continually evolving, with new innovations such as microwave-assisted vacuum freeze drying and vacuum foam drying being developed.

Conclusion

Vacuum freeze drying has revolutionized the food preservation industry by overcoming the limitations of traditional preservation methods. The process is effective in preserving the nutritional content and flavor of food products while extending their shelf life. Vacuum freeze-dried food products have numerous applications in the food industry and are popular among consumers who value convenience and quality. As the technology continues to evolve, vacuum freeze drying is expected to play an even more significant role in the food preservation industry.